During the Covid-19 pandemic period, attending a Pre-Delivery Inspection became a challenge for one of our US customers. While time for delivery was critical (and weeks of quarantine undesired) we at DTS searched for a solution. And found one!

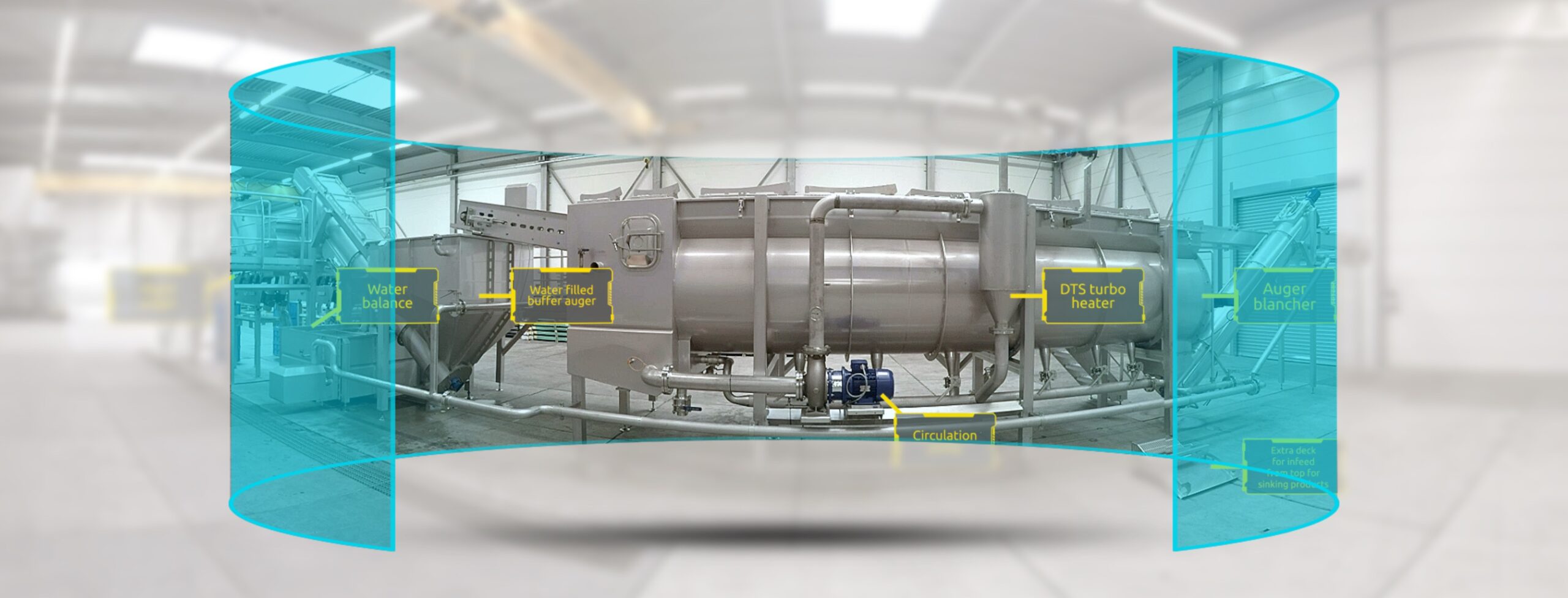

At DTS we built auger conveying and thermal processing solutions for various business segments of the food processing industry. Early in 2020 we were rewarded a processing line to prepare whole mini-cucumbers, red and green peppers and other whole products to be canned for one of our customers in the US. Part of the agreement was to perform a wet commissioning of the system with product during the pre-delivery inspection.

At DTS we have the space available and are equipped with the tools and people to perform this service. As the customer was unable to travel to us due to government restrictions, we have contracted our marketing partner to shoot a 360 degree video with a unique multi – camera tool while we ran the line. The customer was able to attend the test on an Oculus VR Headset that we shipped to them. The system works interactively so that the viewer can decide where to go and what to zoom into.

Unable to attend your next PDI at DTS? Or no time available? Ask us for what we can do!